Artificial intelligence technology is becoming increasingly prevalent across various industries, including water and wastewater management. The annual CWEA conference will feature sessions that demonstrate how AI, algorithms, and machine learning can benefit plant operators and enhance the wastewater treatment process by boosting efficiency. Attendees will have the opportunity to witness the potential of these technologies first-hand.

Joshua Registe, an environmental engineer from Jacobs, will present two case studies during one of the conference sessions. These case studies demonstrate how wide-scale machine learning algorithms can be used to effectively ingest all available data, providing actionable insights and recommendations to operators. This approach enables operators to fully leverage big data, cloud technology, data science, and wastewater subject matter expertise.

“For those unfamiliar with machine learning, this is a form of artificial intelligence that enables computers to learn and make decisions without being explicitly programmed to do so,” Registe said. “Instead, there are many machine learning algorithms that use different statistical techniques across streams of data to enable a computer system to learn patterns and make predictions.”

To put it simply, machine learning is a process that involves inputting data into a computer, which then identifies patterns and relationships within the data. This process is also known as training a model. Once the model has been trained, the computer can use the examples provided to make predictions or decisions on new data without requiring explicit programming for the task. Machine learning is widely used in applications such as image recognition, natural language processing, forecasting, recommendation systems, and predictive analytics.

“Machine learning also has the ability to uncover valuable insights and patterns that allow us to deploy predictive models that help operators migrate from the reactive style of operations to enabling more proactive decision-making,” Registe said. “Predicting future conditions based on real-time data, and more importantly, allowing operators to design to the specific future that they want on any given day as it relates to water quality or consumption, or maintenance, has proven to be very valuable with still much more potential to unlock.”

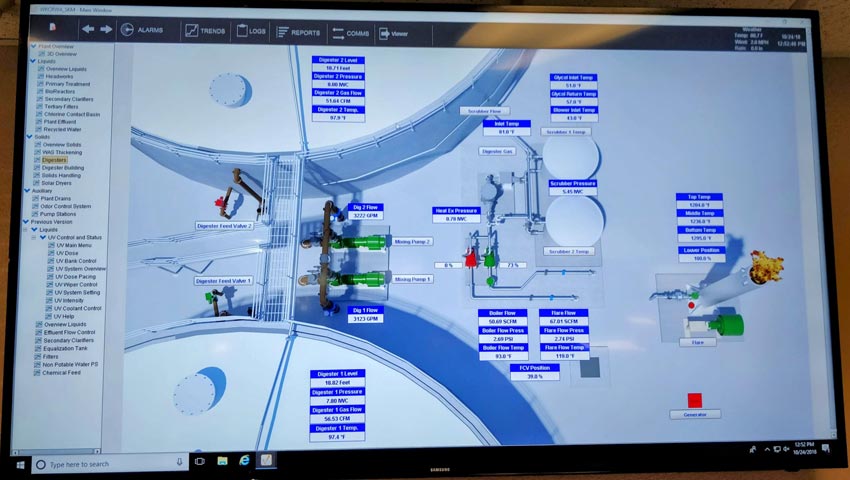

Water and wastewater facilities have a plethora of sensors and data that can be utilized for machine learning purposes. By employing data science and machine learning techniques, it becomes possible to capture all the crucial procedural knowledge of how operators would react to different operational events.

Registe will cite two case study examples in his presentation. The first is the Agua Nueva Water Reclamation Facility in Tucson, Arizona, a 32 MGD wastewater facility with screens, dissolved air flotation, five-stage Bardenpho process, tertiary filters, and a chlorine disinfection facility. The second case study involves the Wilmington WWTF in Wilmington, Delaware, a 340 MGD wastewater facility with screens, primary settling, secondary treatment (BOD), polishing ponds, and chlorine disinfection facility.

Both are examples of wastewater plants that have implemented AI and Bayesian modeling frameworks to improve their operations. Agua Nueva focuses on reducing aeration energy expenses and improving nutrient management, while Wilmington optimizes disinfection chemicals. AI algorithms are used for both forecasting future conditions and predicting water quality. Post-deployment, both sites have seen significant savings, ranging from 10% to 30% in energy or chemical usage. Registe explains that these case studies demonstrate the successful implementation of AI at treatment facilities and show how it can empower plant operators and improve efficiencies in wastewater treatment.

According to Registe, organizations looking to develop an AI and machine learning program can begin by identifying quick wins for optimization in specific areas of interest. They should then assess the availability and limitations of data and gradually build digital solutions.

“A phased approach can allow organizations to be flexible and adapt to realize the value early on without having to build all components at once. Breaking the transformation journey into smaller achievable goals,” he said.

Registe has worked for Jacobs for two years, where he developed and deployed various types of machine learning, mechanistic, and hybrid models, both as on-premise and cloud solutions. He has seven years of experience in statistics, data visualization, data management, predictive analytics, and machine learning. Registe is also a licensed professional engineer with expertise in wastewater facility environmental planning, analysis, and design.

Registe has specialized knowledge in applied science and research in disinfection, energy, nutrient removal, solids, and biogas treatment. He has an undergraduate and graduate degree in environmental engineering, as well as a graduate degree in data science.

Don’t miss this presentation at the upcoming Annual Conference on Thursday, April 11 at 1:55 p.m. Details here