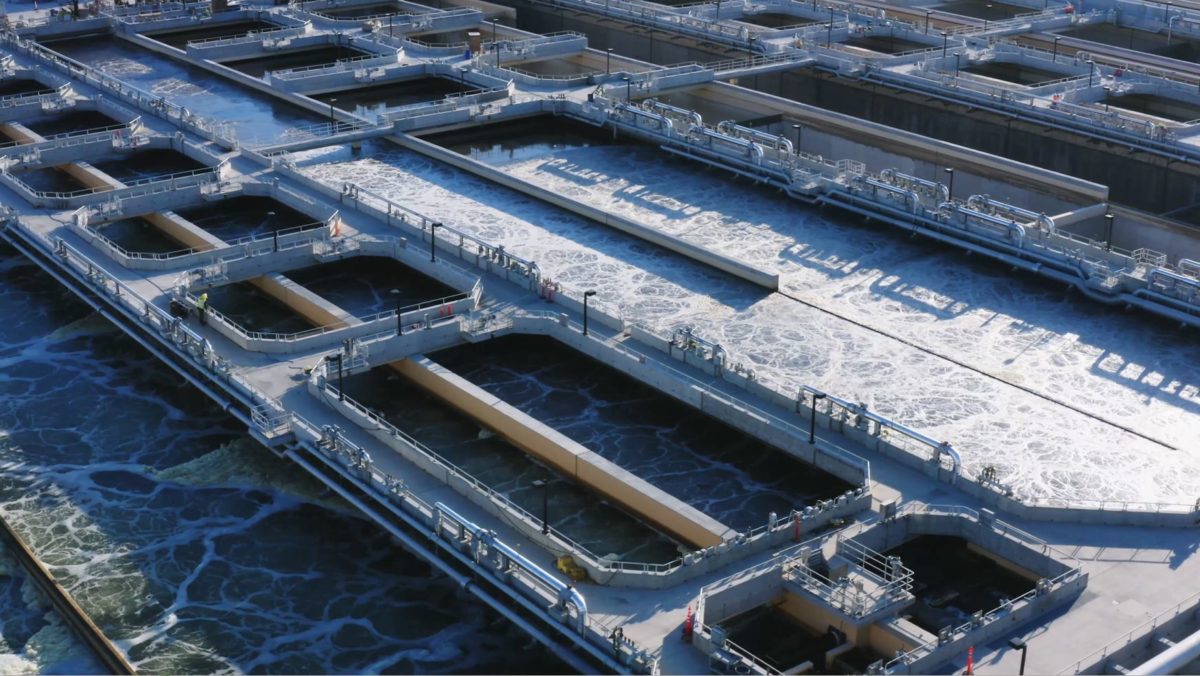

Biological nutrient removal system aerial photo (Regional San)

![]() In 2010, the Sacramento Regional County Sanitation District (Regional San) faced a daunting task—upgrading its wastewater treatment process to tertiary to meet new National Pollutant Discharge Elimination System (NPDES) permit requirements.

In 2010, the Sacramento Regional County Sanitation District (Regional San) faced a daunting task—upgrading its wastewater treatment process to tertiary to meet new National Pollutant Discharge Elimination System (NPDES) permit requirements.

That meant removing nearly all ammonia and nitrates from more than 100 millions of gallons of wastewater received every day. To meet the requirements, Regional San would need to make extensive infrastructure and technology upgrades at its facility that was last updated in the late 1970s.

Regional San owns and operates a network of wastewater conveyance pipes and the Sacramento Regional Wastewater Treatment Plant, located near Elk Grove. Regional San provides wastewater conveyance, treatment, and disposal services for 1.6 million people throughout the Sacramento region. It is the largest discharger to an inland water body west of the Mississippi River.

At the heart of the permit requirements was producing quality water that would eventually reach the Sacramento-San Joaquin Delta. As with all wastewater agencies, Regional San is regulated by state and federal governments under the Federal Clean Water Act of 1972 and 1977.

The Central Valley Regional Water Quality Control Board (Central Valley Water Board) set a very high bar for Regional San in 2010 due to its location upstream from the fragile Delta ecosystem.

“The goal was to reach Title 22 regulations to make the water absolutely protective downstream uses,” said Patrick Pulupa, executive officer of the Central Valley Water Quality Control Board who approved the 2010 permit.

Upon completion, the upgrades would improve treatment processes at Regional San’s plant, which in turn would enhance the Sacramento River water quality and possibly help alleviate ecological problems in the Delta. Regional San’s effluent is discharged into the Sacramento River, which flows into the Central Valley where it flows through the Delta and ultimately to the Pacific Ocean.

The Delta makes up about half the total river flow in the state, supplying water to more than 1 million acres of farmland and drinking water for 25 million people.

“When complete, the project will provide benefits to millions of people throughout the state and to everyone who depends on the bounty of California’s harvest,” Pulupa said

Once the permit requirements were in hand, Regional San assembled a team of consultants and staff to determine the best course of action.

“The 2010 permit didn’t specify what had to be built, just what the water quality needed to be,” said Christoph Dobson, Regional San’s general manager. “The permit emphasized two important factors—ammonia reduction and increased pathogen removal.”

Regional San built a pilot plant to first test different wastewater treatment trains and see which train best met the NPDES permit requirements at the lowest cost for ratepayers. Soon, the EchoWater Project was born. From building the pilot project in 2012, to the completion of the upgrades by 2023, the EchoWater Project will have taken more than 10 years to plan, design, and build. Pulupa said that when permit requirements are taken into account, it is not uncommon to need 13 years to complete such a large project.

The pilot project determined that ammonia and nitrate removal was best accomplished with the biological nutrient removal (BNR) process, which replaced the existing pure oxygen secondary treatment process. The pilot also determined that the best process for the tertiary treatment facility (TTF) included granular media filtration, using liquid chlorine for disinfection. The evaluation process revealed that removing high ammonia-laden flows from solids storage basins and biosolids recycling facilities would be beneficial, requiring a sidestream treatment facility upstream of the main processes.

The significant upgrades of the EchoWater Project include advancing the existing plant from secondary level to tertiary, a BNR project, flow equalization project, a channel aeration blower, nitrifying sidestream treatment project, Bradshaw equalization structure, main electrical substation expansion, disinfection chemical storage project, and various buildings and structures.

A team of engineering consultants partnered with staff to manage the construction of the EchoWater Project—all while continuing to fully operate and treat about 136 million gallons of wastewater per day. In the winter months, where there are no drought conditions, that number can triple.

Currently, Regional San’s BNR project is online and working as planned. The process can clear approximately 99% of all ammonia from the treated wastewater, and the previous process yielded ammonia levels at 35 to 40 milligrams per liter. BNR is not new technology and is employed in many fashions at different facilities, but according to Dobson, there are few BNR plants this large.

Regional San’s BNR treatment facility is 39 acres, equivalent to 18 football fields. To build, it took 35,000 tons of steel and 350,000 cubic yards of concrete.

The site consists of eight large basins lined with thousands of tubes that release oxygen into the wastewater. The oxygen supports bacteria, which remove most of the organic matter and nearly all of the ammonia from the wastewater.

“The basins are being built to piece together, so there are four or five currently operational and working daily,” Dobson said.

This part of the project includes building 25-foot deep basins, a pump station, six aeration blowers, and four electrical buildings. Planning for the BNR began in 2012 and took about three years. Dragados USA began construction in 2016, and the process came online in 2021.

The BNR process was made to be flexible for future needs.

“There are more nutrients that may need to be removed, like phosphorus, for instance,” Dobson said. “There is more than enough capacity in the system for the expected growth in the Sacramento area. If anything, considering reduced flows from the drought, there has been a reduction in water use leading to more capacity in the system since the project planning began.”

Many factors went into deciding the best wastewater cleaning process, based on the type of wastewater that was coming into the facility. For example, Dobson explained that a combined wastewater and stormwater system upstream of Regional San meant it would be difficult to use ultraviolet light for disinfection within the new plant.

In the end, Regional San chose a granular media filtration method with sand and charcoal for the TTF. Granular media filtration is a process that removes suspended solids that remain after sedimentation clarification. It reduces turbidity and improves clarity by removing various particles from coarse sediment. Chlorine is then used to disinfect the treated wastewater.

Balfour Beatty was hired to construct the TTF. The advanced tertiary level of treatment applied to 243 million gallons a day is applied to secondary effluent after undergoing the BNR process. The project encompasses a multi-unit processes: a filter influent pumping station conveys secondary effluent from the existing channel to the granular media filtration inlet structure. There, it passes through drum screens, pump wet wells, discharge headers, and flow metering.

The TTF’s granular media filtration includes a seasonal flow diversion structure, chemical mixing, granular media filters, filter backwash systems, equalization basins, and backwash return pumps. This effluent is filtered downstream and conveyed to the disinfection contact basins.

During wet weather and higher flows, up to 100 million gallons per day of excess effluent discharge that meets permit standards can be conveyed to the effluent pump station and discharged into the Sacramento River.

Using the TTF method of cleaning will produce cleaner water for discharge to help protect the Delta downstream.

Photos by Regional San

In the beginning stages of planning, the EchoWater Protect was estimated to cost between $1.5 to $2.1 billion. Now that the project is almost complete, the budget remains on target at $1.7 billion. Regional San was able to secure a low interest loan of $1.4 billion of the needed money from the State Water Resource Control Board’s State Revolving Fund. The District also had cash and issued bonds early in the project to help keep rates low for customers.

“The ratepayers are now paying $37 per month, and we project that rate will stay flat,” Dobson said.

Regional San encompasses an area that has the potential for quite a bit of growth. According to Dobson, in the past decade, the service area has increased by 30,000 homes, or about 5%.

Once the EchoWater Project is complete is 2023, Dobson said Regional San will be able to provide Title 22 recycled water for food crops to southern Sacramento County farmers.

“Currently, these farmers are using groundwater to water crops,” he said. “Using Regional San’s recycled water will greatly reduce the need for pumping groundwater.”

He said a significant environmental benefit is that when farmers use recycled water, they will save the groundwater so it will have a chance to help feed the Cosumnes River, which during drought years goes dry. The water will also help local riparian forests, benefiting habitat areas for wildlife and migrating birds such as the Sandhill Crane, which arrives from as far away as Siberia and Canada every year.

“The difference will really be seen over the long haul,” Dobson said. “But, within the next 15 years, the groundwater table is expected to rise up to 35 feet.”

Dobson reflected on the entire EchoWater Project and noted it is an excellent example of Regional San’s approach to business.

“It exemplifies Regional San’s ongoing dedication to the protection of public health and the environment, all the while keeping rates low. The EchoWater Project will be completed on time and on budget,” he said.